IBM 5 in 5: Smart sensors will detect environmental pollution at the speed of light

In five years, affordable sensing technologies deployed near natural gas extraction wells, around storage facilities and along distribution pipelines will pinpoint invisible leaks in real-time, and with the help of Artificial Intelligence, deep analysis and insight extraction will be possible from continuous sensor data.

Our team brings together a variety of disciplines including silicon photonics, spectroscopy, materials science and physical analytics to create new sensing technologies that can pinpoint and monitor the quality of our environment. Why? Because we believe that a multidisciplinary, collaborative approach is what’s necessary to help prevent pollution. And that’s also why we’re working with natural gas producers such as Southwestern Energy to explore the development of an intelligent methane monitoring system, as part of the ARPA-E Methane Observation Networks with Innovative Technology to Obtain Reductions (MONITOR) program .

Methane is the primary component of natural gas and considered a cleaner energy source than coal. But if methane leaks into the air, it absorbs the sun’s heat, warming the Earth’s atmosphere. In fact, methane is estimated to be the second largest contributor to global warming after carbon dioxide (CO2).

In the United States, emissions from oil and gas systems are the largest source of atmospheric methane. The U.S. Environmental Protection Agency (EPA) estimates that more than nine million metric tons of methane leaked from natural gas systems in 2014 alone. Measured as CO2-equivalent over 100 years, that’s more greenhouse gases than were emitted by all U.S. iron and steel, cement, and aluminum manufacturing facilities combined. The impact is undeniable.

Our prediction

In five years, affordable sensing technologies deployed near natural gas extraction wells, around storage facilities and along distribution pipelines will pinpoint invisible leaks in real-time, and with the help of Artificial Intelligence, deep analysis and insight extraction will be possible from continuous sensor data.

Why will this change the world?

Sensor systems that can “see” will extend their detection capabilities beyond methane to other contaminants as well: Sensing oil residue in water, harmful pollutants from vehicle exhaust and other particulates in the air, helping us better protect the environment by illuminating it in new ways, in real time and with local relevance. Over time, this technique could help unlock the full potential of cleaner natural gas energy, as well as determine levels of all hazardous chemicals in the environment.

What are the underlying technologies?

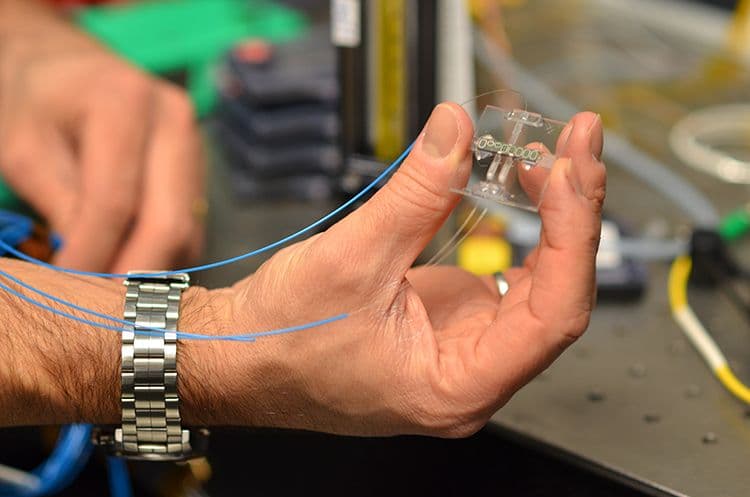

Our work is based on silicon photonics, an evolving technology that transfers data by light. A tiny silicon photonic chip spectrometer – arguably the world’s smallest – could be embedded in a network of sensors on the ground or within infrastructure, or even fly on autonomous drones; generating insights that, when combined with real-time wind data, satellite data, and other historical sources, can be used to build complex environmental models to detect the origin and quantity of pollutants as they occur.

Related posts

- ReleaseKim Martineau and Mike Murphy

IBM Research Ireland moves to the heart of Dublin with a new lab at Trinity College Dublin

NewsMike MurphyHow to make AI models more accurate: Embrace failure

ResearchPeter HessRemembering Dick Garwin, renowned engineer and advisor

NewsMike Murphy